|

QUANTUM BE’S INTRODUCTION TO HEIJUNKA

PLANNING: |

||||||

|

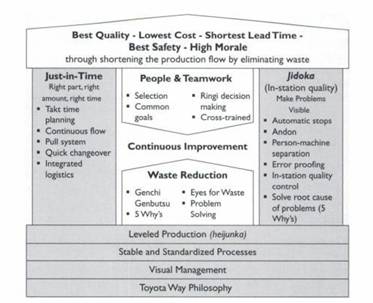

Representation of the

|

Interpretation of Heijunka’s role

|

|||||

|

3- Stock management |

||||||

|

Example of a High Level Visual Quantum Heijunka KPI tracking set (Production line Level). |

||||||

|

This KPIs are used to “pre-process” information prior to import into the Quantum Heijunka Planning algorithms. |

||||||

|

The daily follow-up of these indicators is useful to Plan for Minimum Stock (rule Nb 3 of lean operations) and |

||||||

|

- measure the stock level effectiveness of the operational improvements - understand how operational constraints should evolve and when they require upgrades - understand rapid short term stock level trends shift independently from the “official” forecast - identify need for change in strategy & short term sales / operational tactics - measure the effectiveness of budget and marketing planning - more >>> |

||||||

|

These KPI must typically be complemented by SKU-specific indicators following Sales / Production / Stock |

||||||

|

|

||||||

|

The graph above shows KPIs measuring Heijunka in action, with, simultaneously: 1- Reduction of stock (in days) for high stock items 2- Reduction of the number of Skus having no stock 3- Reduction of items in Back-order status This graph must be read in conjunction with the graphs of 1- sales and 2 – production to see that Heijunka also features: 1- Increased level of sales 2- Increased level of production

|

||||||

|

Batch-to-Stock is the opposite

of Heijunka. |

||||||

|

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

|

Important Notes and Considerations regarding Heijunka |

||||||

|

Heijunka is a mandatory pre-requisite to any Lean Project implementation. It is one of the 4 foundational stones of the TPS )Toyota Production System), and Heijunka production leveling is necessary for the TPS pillar to deliver sustainable results (these 2 pillars are Just-In-Time and Jidohka (autoNOmation) |

||||||

|

It is only the combination of efficient Heijunka planning with Jidohka, JIT and other Lean 6-sigmas tools that can deliver sustainable improvement over the long term (sustain is the 5th. S in “5S”) |

||||||

|

If you wish to contact us to discuss how Lean 6-Sigma methodologies can be introduced in your business to improve your operations, please send us an email at lean-6-sigmas-info@qbeonline.com or visit our website http://qbeonline.com |

||||||

|

Navigation to the next Heijunka KPI |

||||||

|

|

||||||