|

Ž

WEAKNESSES

AND LIMITATIONS IN ACTIVITY PLANNING FROM ERP MODULES

Operational activity

planning (marketing, sales, production, procurement, distribution etc ..)

conducted by traditional western ERP systems typically assumes linear

modelling techniques and features min-max stock level management rules as

they were introduced in the 60s 70s). The literature describing the science

of Heijunka and the statistical tools necessary to extract the value

associated to it is very poorly documented outside of Japan (Heijunka being typically

reduced to the efficient but simplistic “Heijunka Box”), and advanced

Heijunka algorithms enabling modern lean businesses to harness the power of

being able to optimize trade-offs between conflicting constraints are

virtually non-existent. Heijunka planning is not taught to graduates students

in Logistics, Operations nor in MBAs.

Ž

STRENGTHS

OF HEIJUNKA PLANNING RULES

At Quantum BE, over the past 6 years, we have developed a number of IT

modular solutions that combine the power of advanced mathematical modelling

with the complexity of conflicting constraint management as they are

perceived at the operational business level (manufacturing sweet-points, HR

limitations, distribution rules, supply chain conditions etc,) to increase

productivity by focusing on the actual implementation of Heijunka principles

in tactical planning. In doing so, we have consistently demonstrated the

ability of our approach to systematically outperform all previously installed

ERP and business planning systems in both the area of material flow and in

financial results. Quantum BE KPIs associated to Heijunka not only provide

client with a faster and more efficient way to make daily tactical

operational decisions, they also provide higher quality insights into short

term market trends that often rightfully challenge the business “politically

correct” official forecasts.

Ž

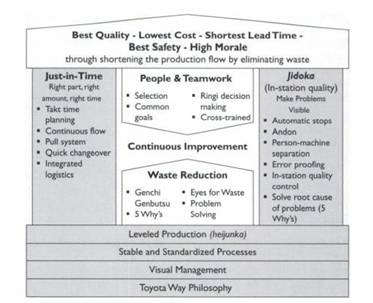

MAXIMIZE

HEIJUNKA’S EFFECTIVENESS IN THE FIELD with JIT and Jidohka

Heijunka planning is foundational to the Lean Philosophy. In the TPS temple

featured above, note that financial rewards (low cost, low waste, 6 sigma

quality and superior market reactivity) are located in the “roof” of the Temple. To achieve results that have a substantial impact on the company’s bottom line, it

is important to work simultaneously on critical projects in the areas of JIT

(continuous flow, pull systems …) and Jidohka (autoNOmation). These “pillars”

must be constructed robustly to enable the temple to sustain its roof. Also

note that the pillars (which feature most of the Lean “Tools”) by themselves

will not support the roof unless the foundation stones are strongly

implemented. Most western companies that consider themselves Lean actually

fail this test.

Ž

BOOST

YOUR LEAN PROJECTS

If you want to learn more about efficient Heijunka planning strategies, or if

you want to contact us for a detailed quotation for how much Quantum BE

heijunka planning could help you save in your overall operation costs, please

contact us at:

heijunka-info@qbeonline.com

Tel = (61) 2 9345 5225

Ž

VIEW

MORE IN RELATION TO A REAL APPLICATION BUSINESS CASE

Click on the 3

following links to see the Quantum BE approach applied to some real-life

business cases. The 3 following pages show examples of graphical displays for

typical KPIs, (sales, production, stock) their daily trends and how to use

them in decision making at the strategic and tactical levels. Click on the

words above to access these KPIs

|